How Plastic Mould Reshapes the "Precision Gene" of the Three Major Industries?

Publish Time: 2025-08-26

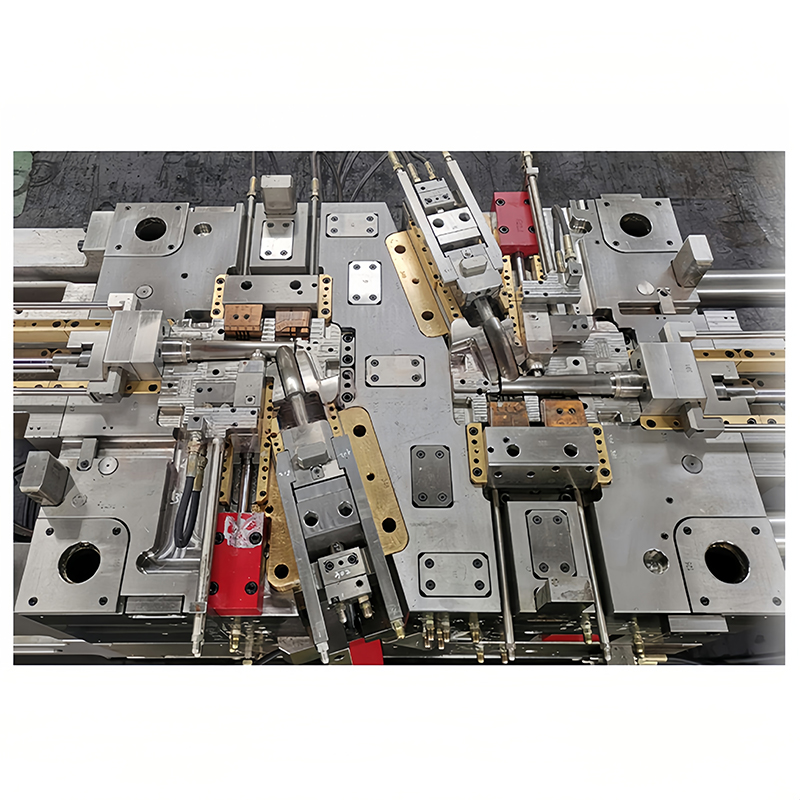

As new energy vehicle interiors begin replacing leather with "breathing" slush molding materials, as smartwatch cases become as thin as 0.3mm yet remain drop-resistant, and as disposable syringes resist deformation at 134°C...plastic molds have long transcended conventional wisdom, becoming the "hidden champions" supporting modern industrial precision manufacturing. From lightweighting in automobiles to sterilization in medical devices, mold technology in these three areas is redefining industry standards with disruptive innovation.Plastic Molds for Automotive Interior Parts: A Perfect Blend of Lightweight, Aesthetics, and Function1. Compatibility with Eco-Friendly MaterialsThe automotive industry is accelerating its transition to electrification, making lightweighting a core requirement. Interior molds utilize micro-foaming technologies (such as MuCell microcellular foaming) to reduce component weight by up to 20%. They also incorporate bio-based plastics (such as castor oil-based polyurethane) and recycled materials, reducing carbon emissions. For example, the Volkswagen ID. series utilizes this technology to achieve weight reduction while maintaining structural strength.2. High-Precision Surface Treatment and Aesthetic DesignMid- to high-end vehicle interiors strive for both tactile and visual enhancements. Slush molding molds use mold etching technology to achieve textures like wood grain and carbon fiber. The surface hardness is as low as 60-80 Shore A, comparable to the feel of genuine leather. The BMW 5 Series utilizes a dual-hardness slush molding layer design: a soft, energy-absorbing surface layer and a tough, impact-resistant bottom layer, effectively protecting occupants in collisions.3. Integrated Molding of Complex StructuresThe Toyota bZ4X's flyweave seat fabric mold achieves seamless, one-piece molding, improving breathability by 30%. The Volkswagen ID.7's Smart Surface technology embeds LED light clusters into the slush molding layer, creating a touch-sensitive backlighting effect. This type of mold utilizes a multi-cavity layout and hot runner technology to ensure consistent molding of complex curved components.4. Rapidly Respond to Customization NeedsNew energy vehicles are increasingly demanding environmentally friendly interior materials, making traditional molds difficult to adapt quickly. Custom molds utilize a modular design, allowing the production of grille designs with varying textures simply by replacing the mold core, shortening development cycles by 40% and meeting the personalized needs of automakers.Industrial Electronic Plastic Molds: A Model of Precision, Efficiency, and Miniaturization1. Ultra-Precision Dimensional ControlElectronic components require mold precision down to the micron level. Medical-grade injection molds utilize five-axis machining centers to ensure part dimensional tolerances of ±0.005mm, meeting the demands of high-precision components such as pacemaker housings. Optical lens molds utilize a mirror polishing process to achieve a surface roughness Ra <0.01μm, ensuring image clarity.2. Miniaturization and Multifunctional IntegrationMicro-injection mold technology can produce plastic parts with dimensions less than 1mm, such as mobile phone SIM card trays and earphone housings. Through a stacked mold design, a single mold can simultaneously mold eight parts, increasing production efficiency by 300%. Smartwatch case molds integrate IML (In-Mold Insert) technology, achieving a seamless integration of metal and plastic with a thickness of just 0.3mm.3. High Efficiency and Automated ProductionHome appliance injection molds utilize a visual intelligent mold temperature control system, increasing cooling efficiency by 25% and reducing the molding cycle time to just 8 seconds. Combined with CAE mold flow analysis, problems such as shrinkage and deformation can be predicted, increasing the yield rate to 99.5% and saving 30% on proofing costs.4. Material Compatibility and Environmental ProtectionThe molds are compatible with biodegradable materials such as PLA and PBS, meeting EU environmental standards such as ROHS and REACH. For example, a company in the Xiaomi ecosystem uses biodegradable plastic molds to produce smart home housings, which have passed EN13432 certification and received positive market feedback.Medical Component Plastic Molds: The Benchmark for Safety, Precision, and Sterility1. Biocompatibility and Sterility StandardsMedical mold materials must pass ISO 10993 biocompatibility testing to ensure they are non-cytotoxic and non-allergenic. For example, disposable syringe molds are made of PPSU (polyphenylsulfone), which withstands steam sterilization at 134°C and does not release harmful substances such as bisphenol A.2. High Cleanliness and Anti-Contamination DesignThe mold structure features a zero-dead-spot design to prevent residual drug solution and bacterial growth. Hemodialysis equipment molds are mirror-polished to Ra <0.05μm and processed using EDM (Electrical Discharge Machining) technology to ensure a microcrack-free surface and reduce contamination risks.3. Precision Manufacturing and Quality TraceabilityMedical molds must comply with the FDA 21 CFR Part 820 quality management system. Each mold is equipped with a unique ID, enabling full traceability from raw materials to finished product. For example, Johnson & Johnson uses laser engraving technology to imprint a QR code on the mold surface, which can be scanned to access information such as production batches and test reports.4. Rapid Mold Changeover and Flexible ProductionTo cope with unexpected demands such as those during the pandemic, medical molds must be able to quickly change molds. Modular mold designs with plug-in components enable model changes within two hours, supporting flexible production of everything from 5ml syringes to 50ml serum bottles.From the "tactile revolution" in automotive interiors to the "sterile evolution" of medical components, every breakthrough in plastic molds is pushing the boundaries of the industry. In the future, with the widespread adoption of technologies like AI mold flow analysis, 3D printing, and nanoscale surface treatment, molds will no longer be mere tools but instead become intelligent bridges connecting design, materials, and manufacturing. In this precision manufacturing race, whoever masters core mold technology holds the key to the future.